News

90KW 120HP 3Bar Oil Free Screw Air Compressor

TUV certificate 0 oil content Oil Free Screw Compressors 35bar 40bar oil free screw compressor supplier

Low Pressure Air Cooled 3 Bar Variable Frequency Screw Air Compressor Direct Driven for rifles de aire comprimido

100% oil free ISO 8573-1:2010 Class 0 certified

250kw/350hp oil free screw air compressor short specification:

Model No.: RMW-350A

Way of transmission: coupling driven

Air flow capaicty: 41m3/min @8bar; 38m3/min @10bar

Power: 250kw/350hp

Lubrication water volume: 300liters

Cooling method: water cooling

Speed: 2970rpm

Outlet connect: DN100

Inlet temperature: atmospheric pressure 2-40℃

Outlet temperature: Cooling water temp.+14℃

Voltage: 380v/415v/220v-3p-50hz/60hz are available

Weight: 5200kg

Dimension: 332*160*184cm

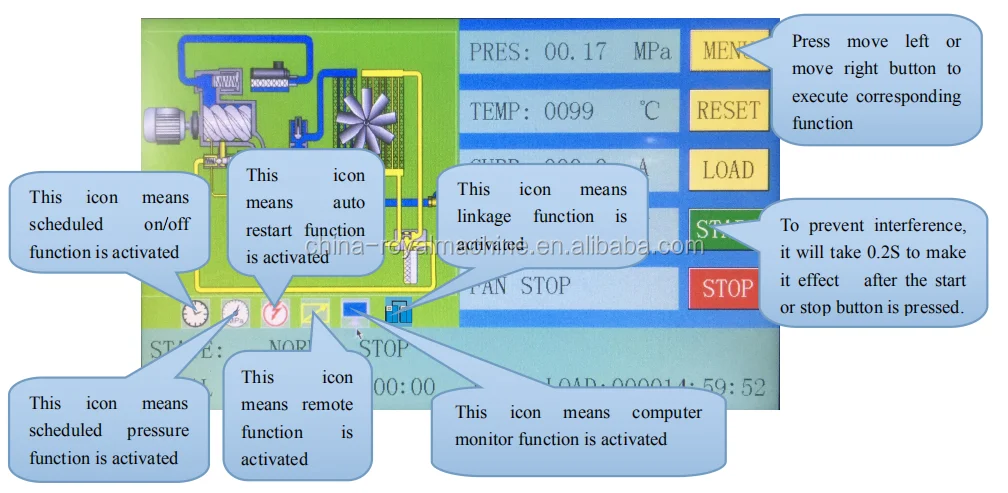

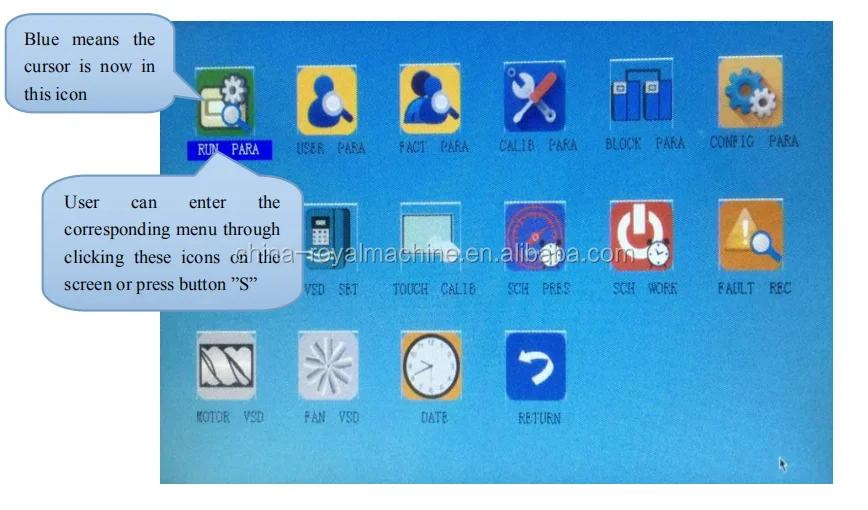

Controller features of this oil free screw air compressor

6” touch screen control panel, user interface for simple and convenient operation.

multiple link control available, no link panel required, meeting various demand from customers.

power saving/local / remote/auto/manual multiple operating modes.

real time alarm and warning display for full control of various conditions.

actively power saving and protect design for efficiency power saving and loading control.

control system functions.

1.Status display

2.Alarm function

3.System time parameters

4.System maintenance

5.Shutdown protection

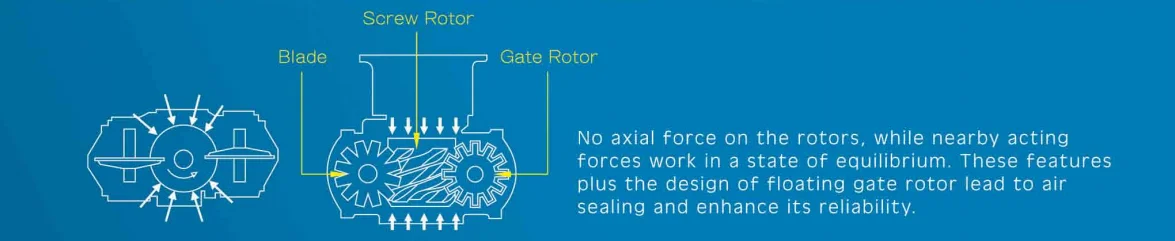

Oil-Free System Structure of the water lubrication screw air compressor

In conjunction with the wear-resistant flat bearing, high performance ceramic bearings constitute a big air chamber between the mechanical bearing seal and the bearing to keep the compression chamber clean, and avoid the influence of compression chamber water & air and vacuum pressure on the bearing. This increases reliability.

High efficiency lubrication water of the oil free screw air compressor

Lubricant water functions

Serves as sealant, coolant and lubricant.

Sealing function reduces/seals “blow hole” between rotors and housing to absolute minimum, ensuring efficient compression with delivered air volume per horse power increased by 15% as compared to general dry-type screw units.

Lubricant water also very effectively absorbs and dissipates heat generated during compression process.

High reliability of the oil free air compressor

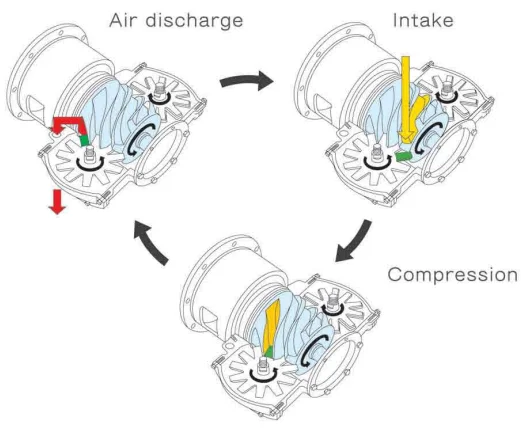

Oil free screw compressor applies rotary single screw air-end.

By being in market every since 1982, it has undergone practical for over 30 years, all of it’s air quality, power saving and high reliability features have turned out to be state of the art in design and performance.

Air and water are becoming a major trend in compressor market due to their high compatibility, availability, reliability and environment friendliness.

Long interval maintenance periods of the oil free screw air compressor

Nearly ideal isothermal compression, direct driven method, smart configuration and precision component design and machining, long bearing service life, all of the above essentially extends interval between regular periodical maintenance.

Near isothermal compression:

Thermal energy and water film, arising from the compressed air cooled by the lubricant water that has being injected into the compression chamber, seals up rotor gaps to prevent air back flow. The ideal isothermal compression thus achieves optimum efficiency. Theoretically, when air at 20℃ is compressed to 7kg/cm2G in a thermal isolation process, the discharge air temperature will be over 250℃, injection of lubrication water that has a cooling effect, into the compression chamber will bring the temperature down to about 40℃, achieving high efficiency ideal isothermal compression.

Full range technical parameters of the oil free screw air compressor

| Oil Free Water Lubricated Screw Compressor | ||||||||||||||

| Model | Way of Transmission | Air flow /Pressure | Power | Inject water volume | Cooling water volume | Way of Cooling | Speed | Connect | Weight | Diemention (mm) | ||||

| m3/min/bar | KW | HP | L | L/min | rpm | inch | Kg | L | W | H | ||||

| RMW-10A | Coupling | 1.16/8 | 1.04/10 | 7.5 | 10 | 27 | Air | 2930 | G1" | 500 | 1100 | 800 | 1000 | |

| RMW-15A | Coupling | 1.56/8 | 1.36/10 | 11 | 15 | 27 | Air | 2930 | G1" | 500 | 1100 | 800 | 1000 | |

| RMW-20A | Coupling | 2.4/8 | 2.12/10 | 15 | 20 | 27 | Air | 2930 | G1" | 600 | 1400 | 1000 | 1200 | |

| RMW-25A | Coupling | 3.1/8 | 2.62/10 | 18.5 | 25 | 27 | Air | 2940 | G1" | 600 | 1400 | 1000 | 1200 | |

| RMW-30A | Coupling | 3.5/8 | 3.13/10 | 22 | 30 | 27 | Air | 2940 | G1" | 655 | 1400 | 1000 | 1200 | |

| RMW-40A | Coupling | 5.0/8 | 4.2/10 | 30 | 40 | 40 | Air | 2940 | G11/2" | 1150 | 1920 | 1170 | 1320 | |

| RMW-50A | Coupling | 6.1/8 | 5.22/10 | 37 | 50 | 40 | Air | 2940 | G11/2" | 1200 | 1920 | 1170 | 1320 | |

| RMW-60A | Coupling | 7.3/8 | 6.13/10 | 45 | 60 | 40 | Air | 2960 | G2" | 1320 | 1920 | 1170 | 1320 | |

| RMW-75A | Coupling | 9.6/8 | 8.6/10 | 55 | 75 | 100 | 150 | Water | 2960 | G2" | 1520 | 1930 | 1320 | 1525 |

| RMW-100A | Coupling | 12.5/8 | 11.42/10 | 75 | 100 | 100 | 200 | Water | 2960 | G2" | 1620 | 1930 | 1320 | 1525 |

| RMW-125A | Coupling | 16.3/8 | 14.52/10 | 90 | 125 | 180 | 250 | Water | 2970 | DN80 | 1800 | 1930 | 1320 | 1525 |

| RMW-150A | Coupling | 19.4/8 | 16.9/10 | 110 | 150 | 200 | 270 | Water | 2970 | DN80 | 3100 | 2150 | 1600 | 1680 |

| RMW-175A | Coupling | 22.21/8 | 20.38/10 | 132 | 175 | 240 | 320 | Water | 2970 | DN80 | 3250 | 2150 | 1600 | 1680 |

| RMW-215A | Coupling | 25.5/8 | 24.0/10 | 160 | 215 | 240 | 400 | Water | DN100 | 4500 | 2860 | 1500 | 1750 | |

| RMW-250A | Coupling | 28.0/8 | 25.0/10 | 185 | 250 | 300 | 420 | Water | DN100 | 4500 | 2860 | 1500 | 1750 | |

| RMW-270A | Coupling | 33.0/8 | 27.0/10 | 200 | 270 | 480 | 640 | Water | DN100 | 4500 | 2860 | 1500 | 1750 | |

| RMW-350A | Coupling | 41.0/8 | 38.0/10 | 250 | 350 | 480 | 640 | Water | DN100 | 5200 | 3320 | 1600 | 1840 | |

We start oil free screw air compressor from design and produce oil free screw air end to complete the oil free compressed air system.

Danfoss solenoid valve, temperature sensor and water coolers for our 40bar oil free screw air compressors:

Air cooling oil free screw air compressor flow chart:

Water cooling screw air compressor flow chart:

Water lubrication oil free screw air compressor photos:

Applications of the oil free screw air compressor

For painting:

Air request:oil free, dew point-23℃ (need oil free screw air compressor)

After equipment:Adsorption air dryer,Line filter

Application:Auto industry,electronic industry

For food industry

Air request:oil free air,dew point -40℃

After equipment:adsorption air dryer, line filter

Application:food industry,medicine indust,electronic industry

For fermentation

Air request: 100% oil free

After equipment: line filter, active carbon filter

Application:Medicine, Food

For cleaning use

Air request: 100% oil free, dew point -40℃

After equipment:adsorption air dryer, line filter

Application:Electronic industry, laboratory

For PET, Transport use

Air request:Oil free,dew point 2℃

After equipment:Refrigerant air dryer, line filter

Application:Cement,fabric, food,medicine

For instrumentation control use

Air request:oil free air,dew point -40℃

After equipment:adsorption air dryer, line filter

Application:Petroleum ,Electronic,Auto,Medicine,Electricity

For medical industry

Air request:Oil free, dew point -40 ℃

After equipment:adsorption air dryer, line filter

Contamination from compressed air is a major source of concern for the food and beverage industry. Modern manufacturing and production facilities use compressed air in multiple ways, increasing the potential for contamination if the machinery is not working properly.

These processes require compressed air to be clean, dry and free of contaminants to ensure your production is running smoothly.

Air Compressor Uses for Food and Beverage Industry Operations:

Packaging — Compressed air is a chief way to make packaging consistent and efficient, as well as provide a clean method to move food, ingredients and other elements across the line.

Food Fillings — Many foods that use a filling, such as pastries, cakes and pies, as well as liquid products use compressed air to enforce a proper fill.

Fluid Pumping — Diaphragm pumps that move liquids into products or specific configurations during the filling or production process also require compressed air for even filling and pumping.

Nitrogen Generation — When nitrogen is used for the packaging process, it often requires filtered compressed air from a very strong compressor.

Air Knives — Compressed air is often used as the clean medium when cutting or peeling foods such as nuts, onions, fruits and vegetables.

Pilot Air — Compressed air is often used by food and beverage producers as pilot air to control grippers, valves, cylinders and other components. Pneumatic components interact with the air but still have high-purity requirements for proper use.

Mixing Foods — Many dry foods can use compressed air for mixing and movement. It is an efficient mixer, but quality controls must be more stringent.

Choose our oil free air compressors, and ask us for more details please.

Our company offer technical support before and after sales, products training as well. we are professional for screw air compressors, all air compressor outlet drawings, install instruction drawings, technical parameters, compressor configuration list are available; all compressor trouble shooting documents are available, besides our after sales team will give support at any time.

For more about our screw air compressors, welcome to contact with us!

Categories

Contact Us

- +86-17301863604

- +86-17301863604

- aircompressor01@outlook.com

- +86-17301863604